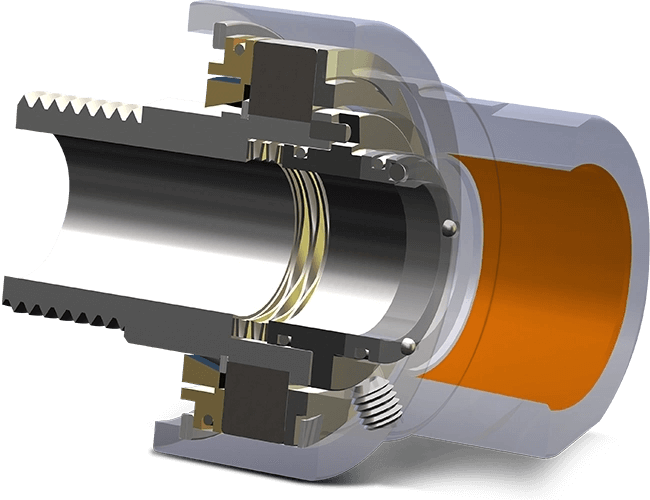

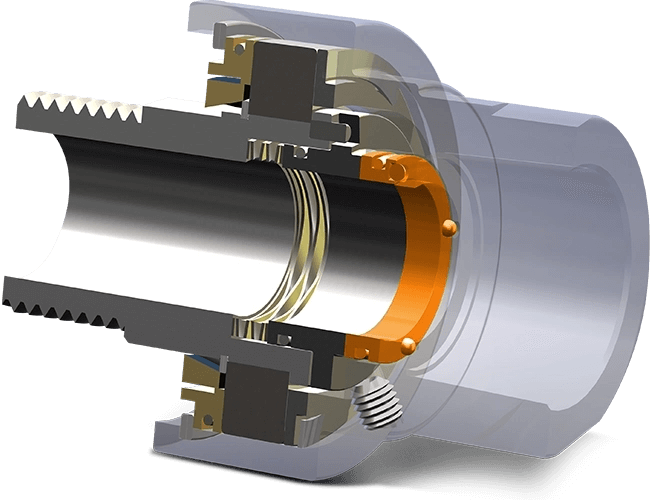

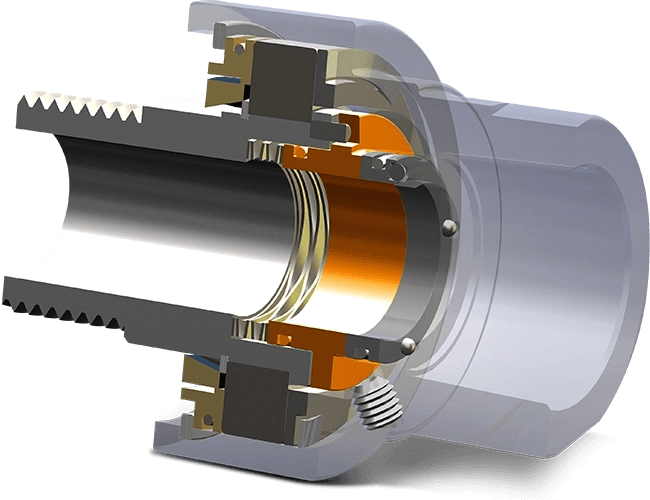

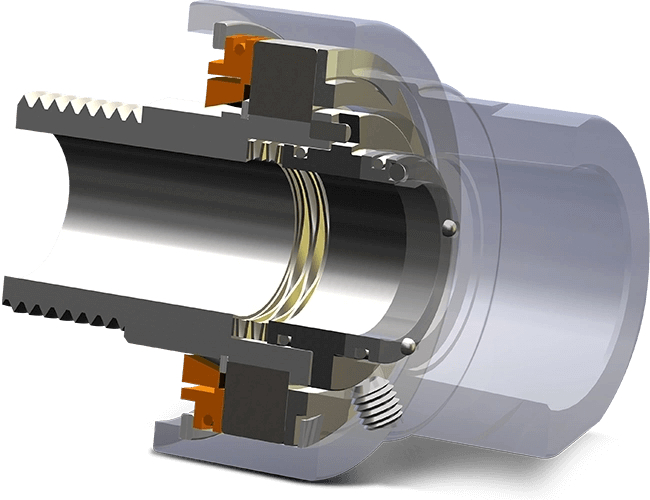

The JO-1 Hose End Swivel

UL Temperature Range: -40ºF to +250ºF

Highest Max Allowable Working Pressure: 400 psi

Highest Hydrostatic Test Pressure: 2000 psi

Full-Circle developed the first swivels to be designed specifically for the 360° rotation of filler valves at the end of a hose for liquefied petroleum gas (LP-gas). Our hose end swivels are available for numerous liquid services including LP-gas, Anhydrous Ammonia (NH3), Natural Gas, and Refined Fuels.

The First of Its Kind

- Prior to the design of our hose-end swivels, drivers constantly struggled to fight the hose.

- With our design, hose end swivels have become the standard in the LP-gas industry.

- This has saved time, hose-twist issues, and money for gas companies all over the world.

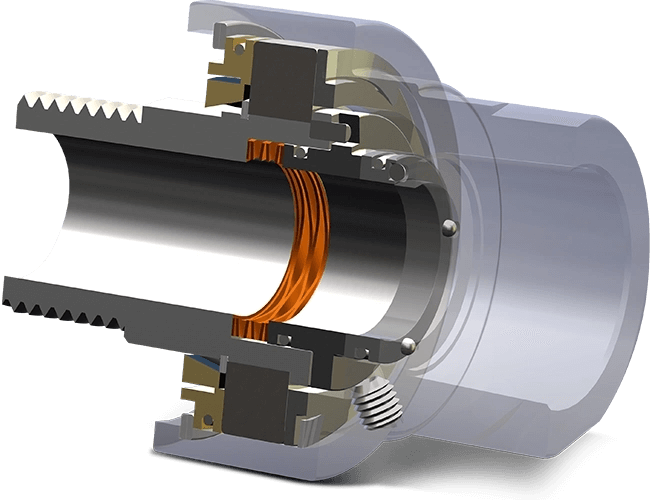

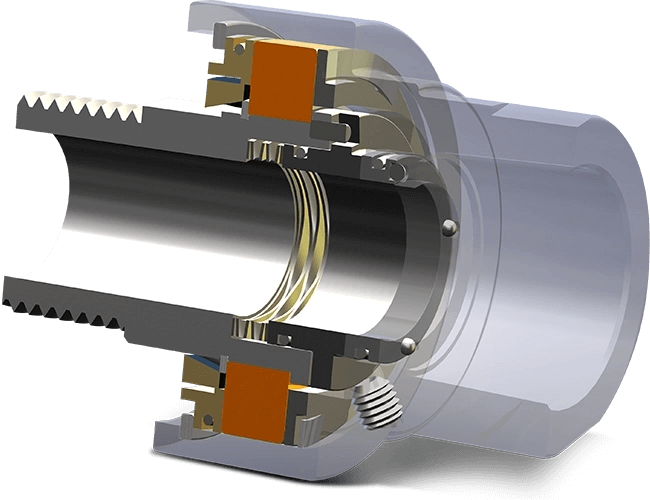

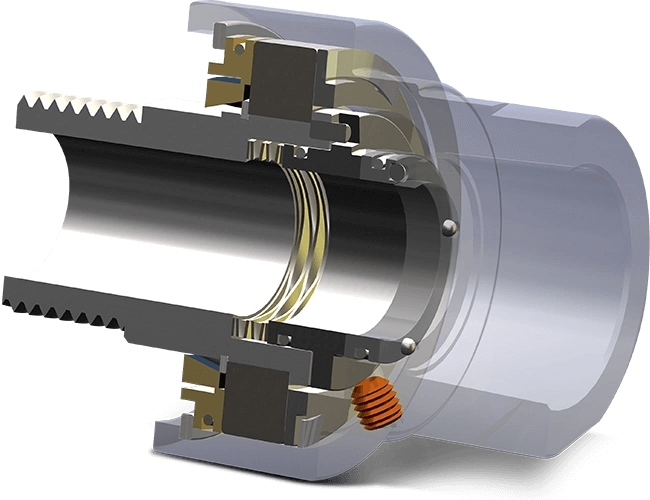

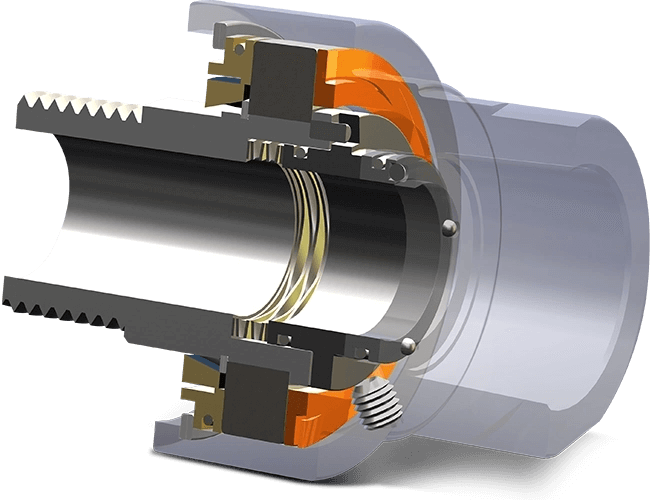

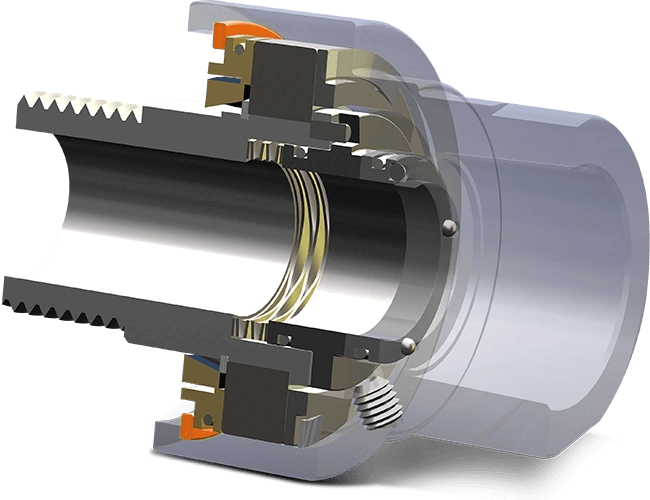

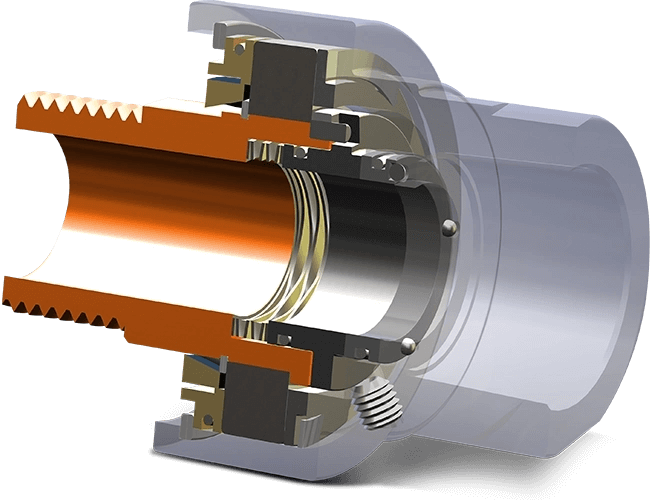

Compact Design

- Two piece balanced seal design held together by system pressure.

- No compressed rubber seals, rotating o-rings, or sandwiched thermoplastic discs.

- No greasing or lubrication ever required.

Stainless steel housing construction.

We Focus on Testing

- U.L. Listed, CE/UKCA compliant.

- Every JO-1 swivel is manometer pressure tested with CO2 vapor to exceed maximum design and safety requirements.

Video Media

The Full-Circle Swivels JO-1

Approvals: Specific swivel models are U.L. Listed for LP-gas, Anhydrous Ammonia, Natural Gas, or Refined Fuels in accordance with the U.L. 567 Standard. Most swivel models comply with the following European Directives and UK Regulations: Pressure Equipment Directive/Pressure Equipment (Safety) Regulations, Machinery Directive/ Machinery (Safety) Regulations, and ATEX/UKEX. EU Declarations of Conformity and/or Declaration of Conformity pertaining to the UK are available upon request. Full-Circle is certified to the ISO 9001 Quality Management System Standard.

Temperatures/pressures indicated above vary based on the liquid service and model swivel. Please contact our engineering department for specific ranges based on your application.