The SMAC Series Swivel Design

UL Temperature Range: -40ºF to +150ºF

Highest Max Allowable Working Pressure: 400 psi

Highest Hydrostatic Test Pressure: 2000 psi

Our SMAC-series swivels are used for a broad variety of applications, designed to assist in the 360° rotation of pipework for Liquefied Petroleum Gas (LP-gas), Natural Gas, Anhydrous Ammonia (NH3), and Refined Fuels. Swivels for other liquid services are also available.

The SMAC-series swivels are designed to be used on hose reels, bulk head delivery systems, and loading arms.

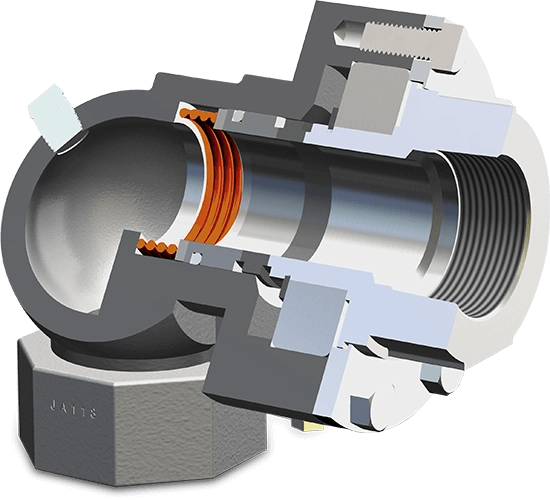

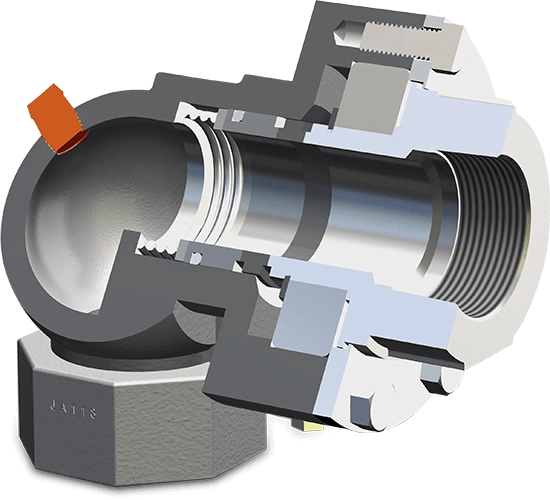

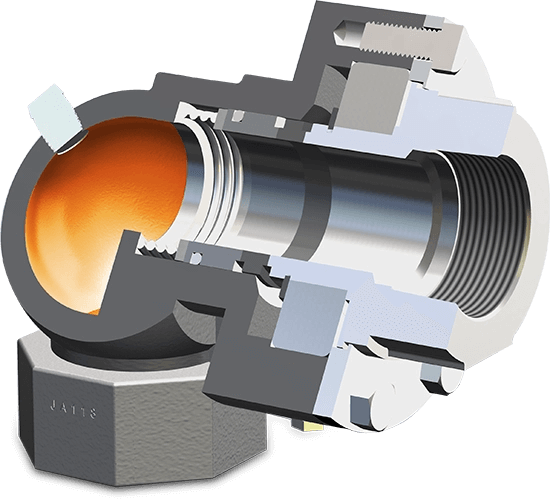

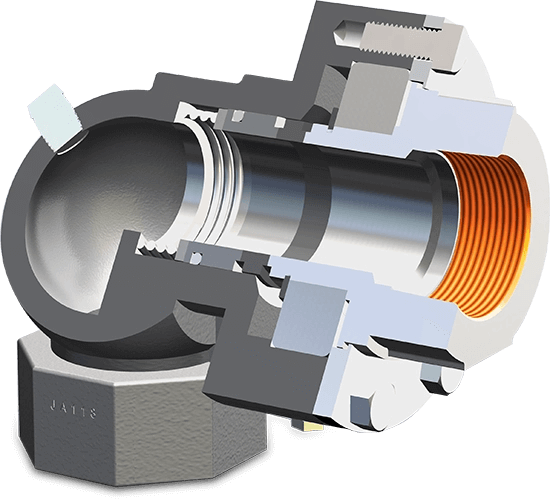

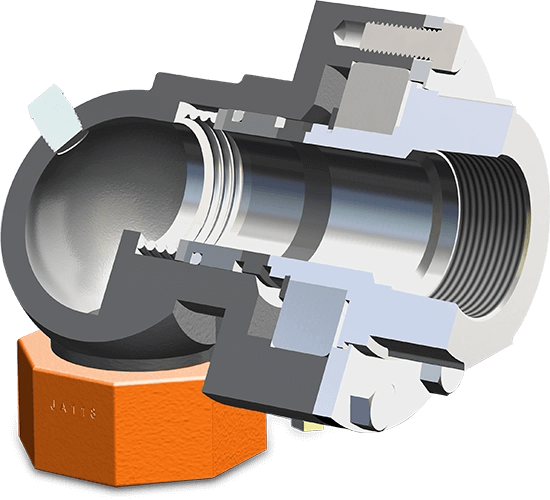

Long Lasting

- High load ball bearing minimizes misalignment problems.

- No greasing ever required.

- Three-piece seal compensates for wear and pipework loading.

- Seals solely by system pressure.

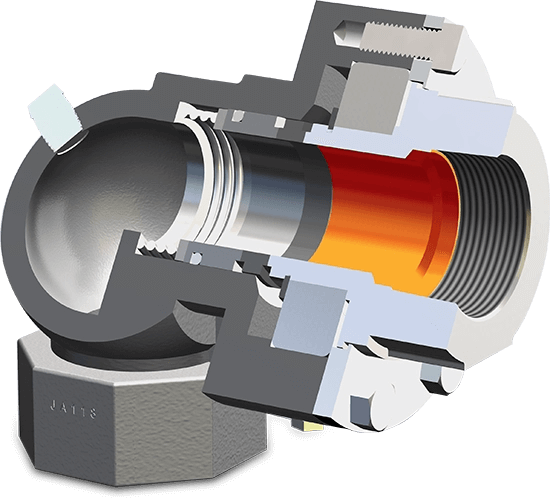

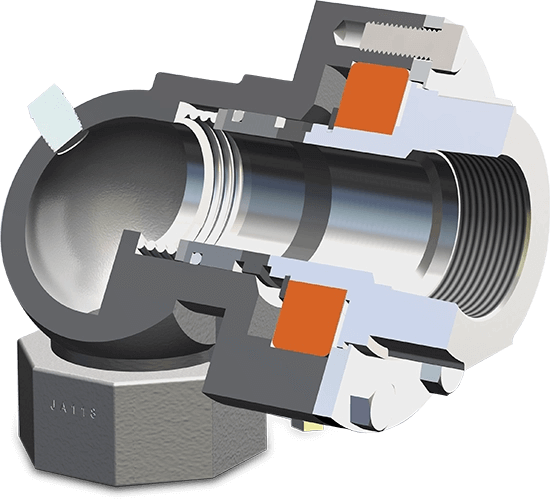

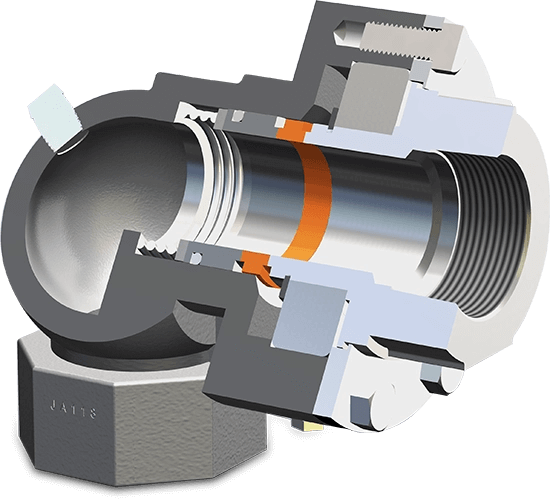

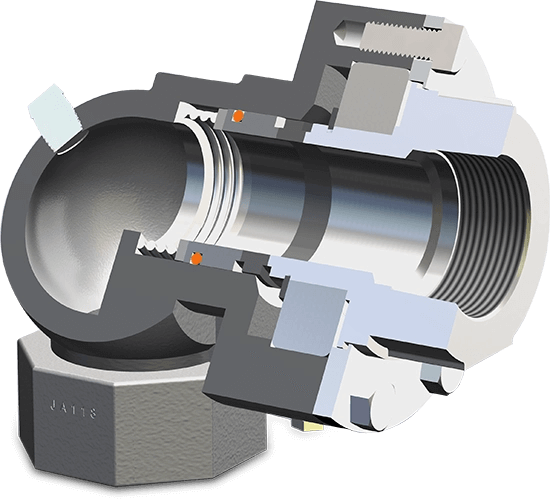

Exceptional Design

- Utilizes a three-piece seal package.

- No wearing rubber seals.

- Compensates for wear.

- Intermediary seal ring rotates at ½ speed, greatly increasing the seal life.

- Options including the “SS” Stainless Steel version for maximum corrosion resistance.

Acute Focus on Quality

- Every swivel is manometer pressure tested with CO2 vapor to exceed maximum design and safety standards.

-

U.L. Listed, CE/UKCA compliant.

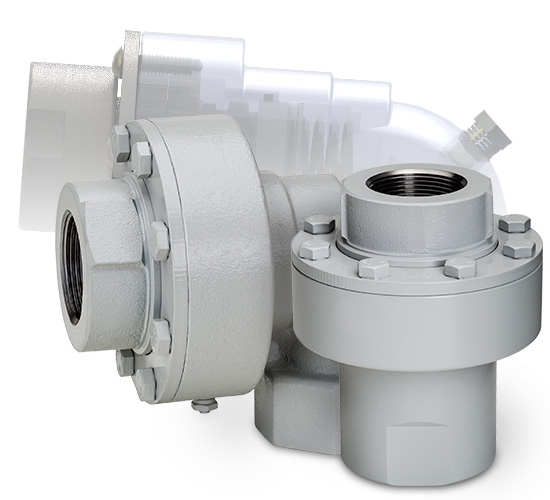

Swivels For Smaller Applications

3/4”, 1”, 1 1/4” SMAC-Swivels

Smaller swivels are offered as the SMAC-3490, SMAC-190, and SMAC-114 which are available in 90° and straight through configurations. Since this swivel is smaller, but must endure the same radial stress when eccentricity (misalignment) occurs, two high-load rated ball bearings are used for maximum performance.

The same type of seal package as used in the larger SMAC-112 and SMAC-200 swivels is incorporated into our smaller pipe size swivels. Available in ¾”, 1”, 1 ¼” and combination thread sizes.

Video Media

The Full-Circle Swivels SMAC-112 and SMAC-200

The Full-Cirlce SMAC-112ST and SMAC-200ST

Approvals: Specific swivel models are U.L. Listed for LP-gas, Anhydrous Ammonia, Natural Gas, or Refined Fuels in accordance with the U.L. 567 Standard. Most swivel models comply with the following European Directives and UK Regulations: Pressure Equipment Directive/Pressure Equipment (Safety) Regulations, Machinery Directive/ Machinery (Safety) Regulations, and ATEX/UKEX. EU Declarations of Conformity and/or Declaration of Conformity pertaining to the UK are available upon request. Full-Circle is certified to the ISO 9001 Quality Management System Standard.

Temperatures/pressures indicated above vary based on the liquid service and model swivel. Please contact our engineering department for specific ranges based on your application.