We’ve been asked many times why we entered the swivel manufacturing business and also how we developed such a revolutionary new design. If not for a few individuals in the right place at the right time, neither would have occurred.

It started with Bob Bailey, who is the Executive Vice President and Chief Operating Officer of Teeco Products, a long standing LP-gas equipment distribution company with headquarters located in California and offices in several western states. In the early spring of 1991, Walter Smith, President of Smith Precision Products Company (Smith Pumps) and John Ives, Smith Pumps Sales Manager, were setting up their booth at a Western Propane Gas Association exhibition in Palm Springs, California.

Bob came over and almost immediately began talking to Walter and John about his interest for a swivel at the end of a bobtail delivery hose to connect the hose to the filler valve. As Walter Smith recalls, he was not necessarily at all interested in designing a swivel, mainly because his company’s expertise involved pumps, and swivels were already manufactured by many companies. Bob made it clear he was interested in a swivel designed specifically for LP-gas that was certified for that use by a third party such as the Underwriters Laboratories. Out of respect for Bob, Walter agreed to go outside and look at a bobtail truck to understand the application. John came out as well, carrying a shaft seal assembly from a pump used for display purposes.

During the course of Bob’s explanation, John gently threw the shaft seal assembly over to Walter and made the remark “Here you go Walt, here is a swivel.” Seeing as a ball bearing is attached to the shaft seal assembly, the shaft can rotate as a swivel would; John was making a joke.

But in that instant, Walter saw it much differently. He states “In my tenure, the light-bulb has never gone off with such intensity as when John threw the shaft seal assembly to me and made the remark he did. After understanding what Bob had already relayed, the design hit me like a ton of bricks.” While John and Bob laughed it up, Walter literally saw the design in his mind. That night a sketch was made on hotel room stationery. Ten days later a crude prototype was being tested.

And, not even a year later, Full-Circle was born with a single product to manufacture; the first swivel Listed with UL for LP-gas service; the model SMAC-1. This design laid the foundation for a remarkable line of swivels to follow.

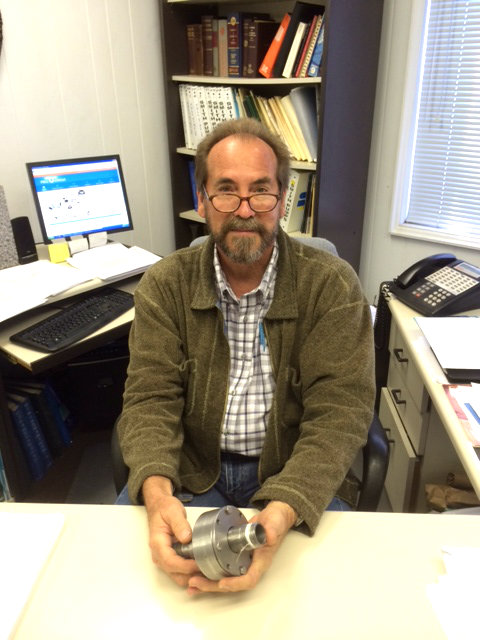

Fast forward twenty three years later; the company is manufacturing hose-end, 90-degree, and straight-through configuration swivels in five different pipe sizes (for bulk head, loading arm, and hose reel use), Victaulic coupled swivels, vent devices for meters, and a new line of stainless steel swivels for systems routinely depressurized (SS-series).

As Walter Smith has stated many times, “We had no preconceived notions of how a swivel was supposed to be designed, so there were absolutely no constraints based on experience with swivel design. We took our extensive knowledge of pumps and mechanical seals, and applied what we knew to develop the Full-Circle swivel. Having no “cobwebs” in the initial design phase was an exhilarating moment in my life that allowed creativity to simply flow.”

Today, Full-Circle products are manufactured at the company’s production facility in Yucca Valley, California, gateway to the Joshua Tree National Park. There, a team of dedicated and talented machinists, assembly/test technicians, and support staff come together to produce highly engineered and world class products specifically designed for the liquefied gas market.